Snap Sorter Guide

SnapSorter Setup & Operating Guide

Thank you for purchasing the Reloading Automation SnapSorter. This device is designed to automatically sort similar-diameter reloadable brass cases into separate containers based on case height.

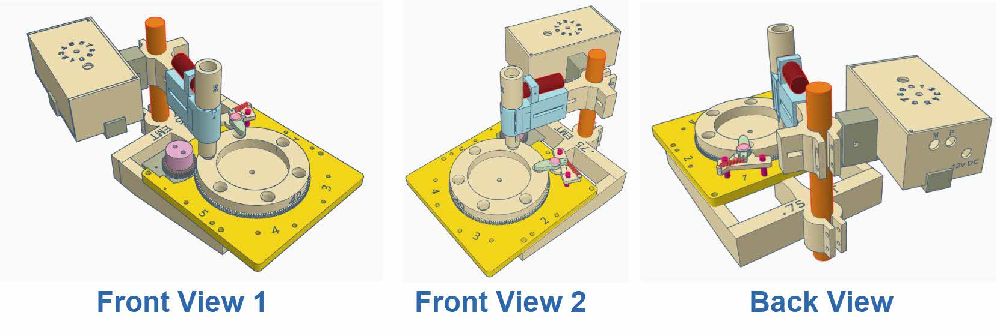

System Overview

The SnapSorter system consists of two primary components:

Base Unit – Mounts to a table or ¾" EMT conduit

Sorter Head (Base Sorter Unit) – Contains the motor, wheel, proximity sensor, and output paths

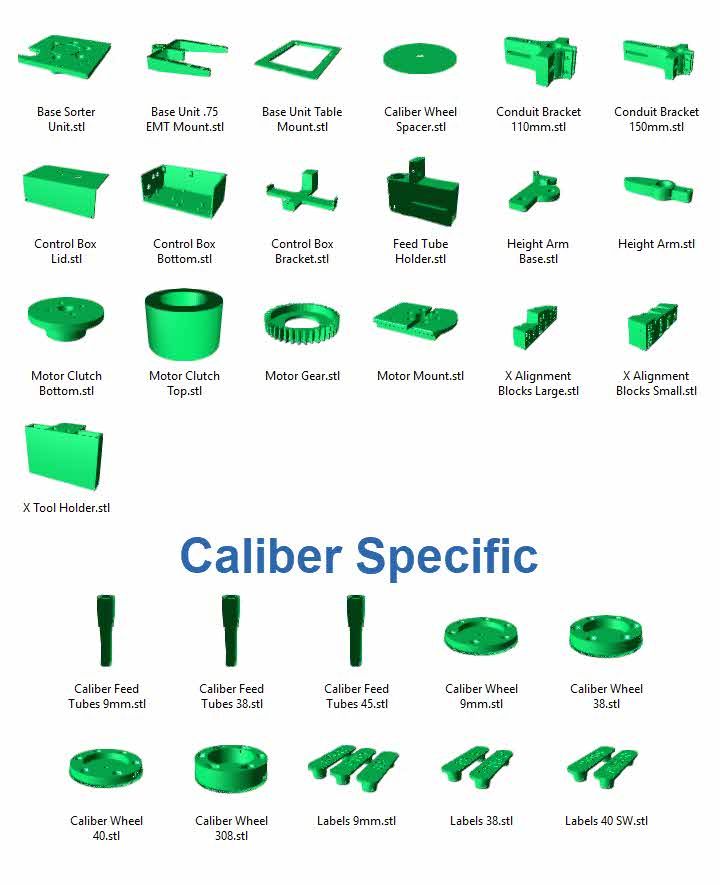

A parts list is provided at the end of this guide.

Mounting Options

Table Mount (Recommended for High Volume)

Mounting to a table provides maximum stability. When using a sufficiently large brass collator, multiple SnapSorters can be mounted 16–24 inches apart, allowing:

Two or more units to sort the same caliber

Feeding into the same output containers

Example:

Two units sorting 9mm can process over 60 lbs of brass per hour, depending on collator speed.

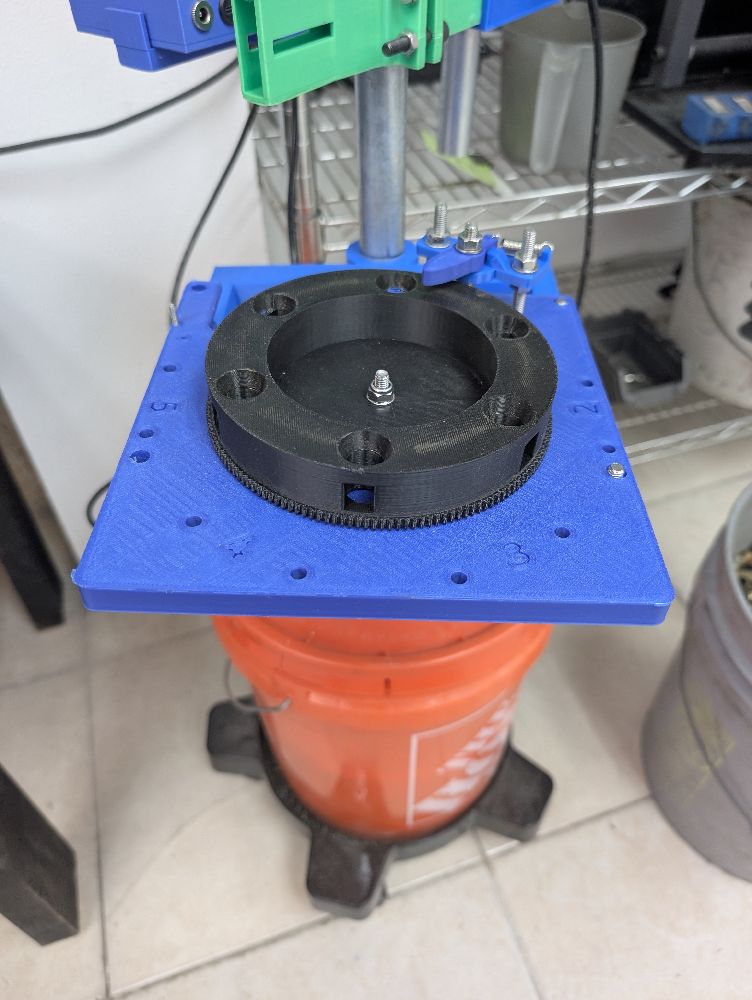

EMT Conduit Mount (Portable Option)

Alternatively, the SnapSorter can be mounted using ¾" EMT conduit:

Insert EMT into a 5-gallon bucket

Fill bucket halfway with concrete

Allow concrete to cure

Place bucket on a rolling cart if desired

This setup allows the unit to be easily relocated as needed.

Before You Begin

After receiving your SnapSorter:

Inspect all components for shipping damage

If anything is damaged, contact us immediately so replacements can be sent

⚠️ Important:

Many components are 3D-printed. Do not overtighten fasteners, as this may cause breakage.

Damage caused by overtightening is not covered under warranty.

Safety

Do not wear rings, bracelets, or loose items that may snag moving components

Always turn power OFF before clearing jams or making adjustments

Assembly & Setup

Step 1 – Mount the Base Unit

Secure the Base Unit to:

Your table, or

The ¾" EMT conduit

Refer to Figure 1 for correct mounting orientation.

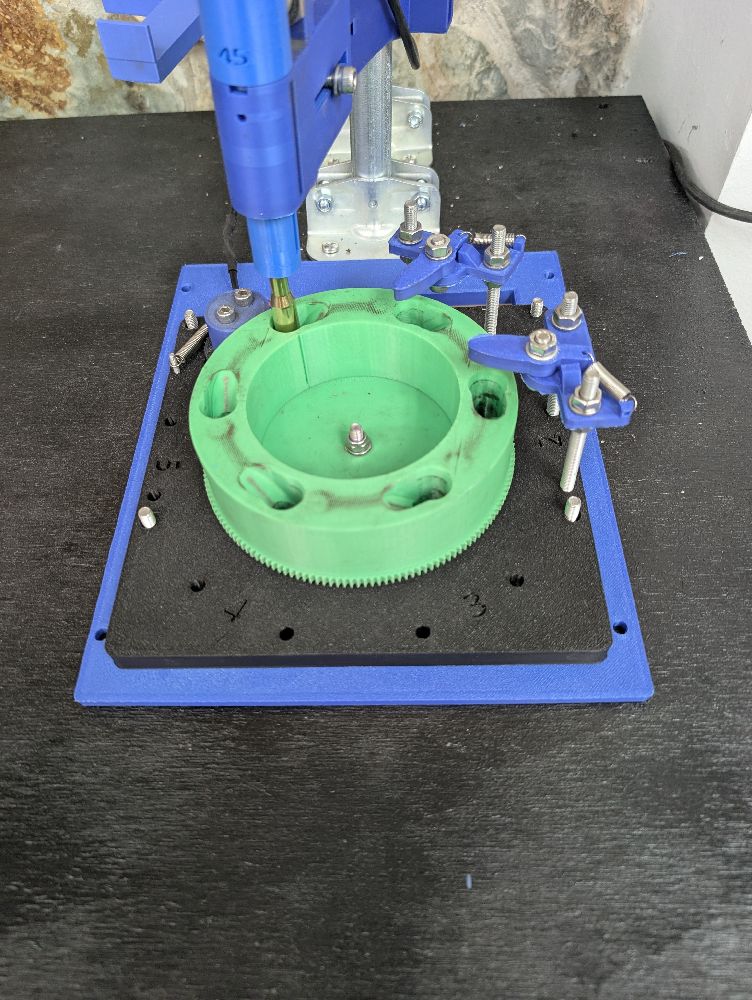

Step 2 – Install the Sorter Head

Place the Sorter Head onto the Base Unit.

Nuts may be installed, but are not required

We typically leave ours unsecured

Step 3 – Install Motor Assembly

If not already installed:

Slide the motor base into the Sorter Head

Attach the spring between the motor plate and the Head

Step 4 – Install Output Tubes (Not Included)

Install case output tubes into the Sorter Head:

¾" OD / 5⁄8" ID tubing

PVC or clear vinyl tubing

10' lengths commonly available at Home Depot

We recommend clear vinyl tubing.

Ensure tubing reaches the collection bucket with extra slack to allow for bucket movement.

Step 5 – Final Assembly

If the Sorter Head was removed during setup:

Reinstall it onto the Base Unit

Step 6 – Adjust Caliber Feed Tubes

There are two adjustments for the Caliber Feed Tubes.

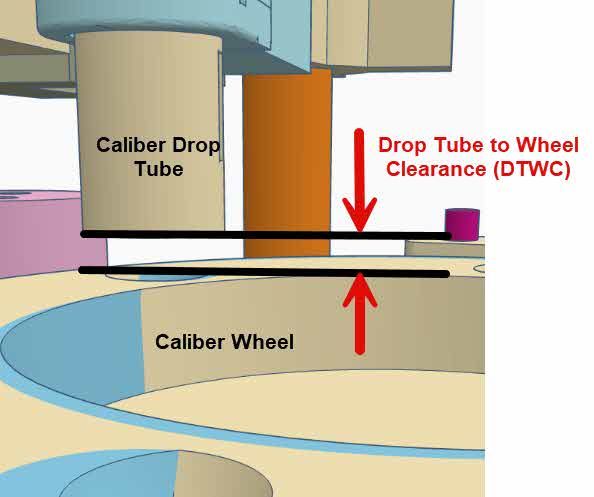

- Adjust the height of the feed tube (DTWC). This is measured from the top (flat) side of the Caliber wheel to the bottom side of teh Caliber Drop Tube. Each sorter size will have a different setting.

- 9mm = 12mm DTWC

- 40 S&W = 13 DTWC

- 38 Special = 14 DTWC

- 308 = 16 DTWC

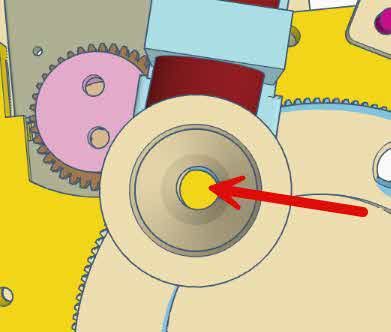

- Looking down adjust the center of the Caliber Drop Tube to be over the top of the drop hole in the Caliber Wheel.

Electrical Connections

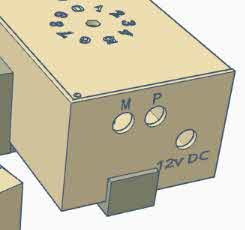

Connect the motor power wire to the “M” jack on the Control Box

Plug the Proximity Sensor into the “P” jack

Plug the 12V DC power supply into the “12V DC” jack

⚠️ Important:

The “M” and “12V DC” jacks use the same connector type.

Ensure the power supply is NOT plugged into the “M” jack.

Double-check all connections before applying power.

Power-On Test

Plug in the 12V DC power supply

Press the Power button on the Control Box

You should observe:

Power button changes color

Proximity sensor LED turns red (no case present)

Wheel remains stopped

Sensor Test

Insert a small metal object (e.g., needle-nose pliers) into the Drop Tube

Sensor light should turn off

Wheel should begin turning continuously

Adjust the speed dial to increase or decrease wheel speed.

💡 Note:

The speed dial includes an OFF position that stops the motor while leaving the sensor powered.

General Operating Guidelines

Brass must be same diameter and similar height

Example: 9mm Luger, .380 ACP, 9mm Mak

Typical height range example:

.380 ACP ≈ 17mm

.38 Super ≈ 23mm

⚠️ Excessive height differences may cause:

Cases falling out

Wheel jams

Cases may be dirty or clean.

Clearing Jams

If a jam occurs:

Turn OFF the SnapSorter and brass collator

Push the Clutch back, away from the spring and Base Sorter Unit

This disengages the motor from the wheel

Rotate the wheel manually to clear the obstruction

If necessary, realign the Drop Tube

⚠️ Important:

Leaving the unit powered during a jam may damage the motor or other components.

Common Issues & Solutions

1. Case Did Not Drop into Output Tube

Release motor and rotate wheel slightly

Check for full output tube (under the Base Unit) backing into the wheel

Empty bucket and clear tubing

2. Cases Not Entering the Wheel

A. No cases detected

Ensure brass is feeding into the Caliber Feed Tube

Red sensor light indicates no cases present

With cases present, the light should be off

B. Feed tube blockage

Check for debris (grass, dirt, corncob, paper)

Check for incorrect caliber blocking the tube

3. Wheel Not Turning

A. Jam at Drop Tube

Clear jam and verify correct tube height

B. Nested cases

Remove nested case from wheel or drop tube

4. Cases Falling Out of Drop Tube

Ensure proper Drop Tube alignment

Reduce gap between Drop Tube and Wheel

Reduce speed for large rifle cases

⚠️ Large cases (e.g., .308, .30-06) rely on gravity.

Excessive speed may prevent full seating and cause jams.

Parts Display