Sorting Range Brass for Reloading: A Step-by-Step Guide

🔍 Why Sorting Brass Matters

Most reloaders reuse brass to save money. Some collect it from their range, others buy raw range brass, and many receive leftover shells from friends or club members.

No matter where it comes from, sorting brass correctly is essential for safety, consistency, and efficiency. You’ll avoid damaged dies, improve performance, and spend less time fixing problems during reloading.

⚙️ “Sorting by Caliber” — What It Really Means

When people say their machines “sort by caliber,” they usually mean case diameter, not true caliber. For example:

.38 Special and .357 Magnum have the same base diameter but are different cartridges.

.45 ACP and .308 Winchester share the same case base size but are completely different calibers.

For reloading, the goal isn’t to group similar sizes — it’s to sort each exact cartridge type.

You want all your 6.5 Creedmoor together, not mixed with 6mm Creedmoor.

All your .45 ACP, not the .45 GAP.

At this point, no machine can perfectly sort mixed range brass into exact cartridges — though it sure would be nice!

🧹 Step 1: Remove Trash, Steel, and Live Rounds

Before sorting, remove all debris such as rocks, targets, and bullet fragments. Toss these out, and separate .22 LR casings into a scrap pile for recycling later.

Next, check for live rounds — this is important. Set them aside safely in a “live ammo” bin for later disassembly.

Use a magnet to pull out steel cases. Don’t assume every brass-colored shell is truly brass — some steel cases are brass-coated. While some reloaders experiment with steel or aluminum cases, it’s not recommended for safety and die longevity.

💡 Pro Tip:

The Frankford Arsenal Media Transfer Magnet is perfect for this step — strong enough to grab steel but with a quick-release handle.

Place steel cases in your steel recycling bin, and toss aluminum into an aluminum bin.

⚙️ High Volume Tip:

If you process large quantities, consider investing in a trommel sorting machine. It automatically removes .22s, trash, and steel cases — saving hours of manual work. Expect to spend $4,000+ for a commercial-grade unit.

📏 Step 2: Sort by Case Diameter

After removing junk and steel, it’s time to sort by case diameter.

For smaller batches:

Shell Sorter by ShellSorter.com — affordable (around $40) and separates cases like .38/.357 from .40/10mm.

For higher volume:

Ultimate Sorter – faster, heavy-duty, and priced between $1,500–$2,000.

Game Change Range Brass Sorter – similar performance and cost.

For industrial-scale sorting:

Roll Sorters from GS Machines handle massive volumes starting at $4,000–$5,000.

This step gets most of your brass grouped by similar diameters, drastically reducing hand-sorting time later.

📏 Step 3: Sort by Case Height

Once your brass is separated by diameter, take each group (for example, .38/.357) and sort by height.

Stand them upright or lay them flat — the difference is easy to spot. A loading block or ammo tray works great for visual sorting.

For automation:

Bowl Sorters handle large volumes (used ~$2,000; new up to $5,000+).

Snap Sorter by Reloading Automation — under $400 (shipped) and requires only a case feeder.

👉 Unlike traditional bowl feeders, the Snap Sorter can also separate rifle brass by family:

6mm / 6.5 Creedmoor

.308 / 7-08 / .243

.30-06 and similar cases

This makes it an excellent time-saver for mid- to high-volume operations.

👀 Step 4: Hand Sorting and Inspection

This is the final and most critical step — and it’s where your eyes matter more than machines.

Check each headstamp, but don’t trust them blindly. Some reloaders convert parent cases (e.g., trimming .44 Magnum to .44 Special, or forming .25-06 from .30-06). Occasionally, even manufacturers mis-stamp brass — we’ve seen “6.5 Creedmoor” brass that was actually .30-06!

When you find incorrect or damaged brass:

Crimp the neck to mark it unusable.

Toss it into your recycling bin.

You can also separate nickel-plated brass or organize by manufacturer at this stage. Many reloaders prefer consistent batches by brand for more uniform reloading results.

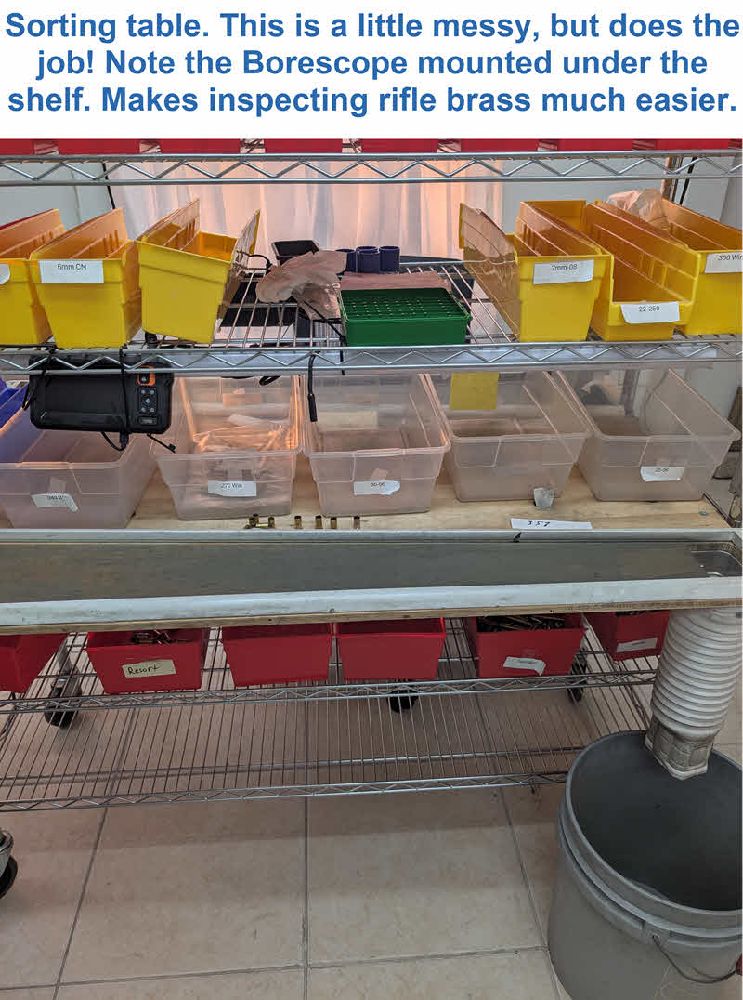

💡 Pro Tip:

Use a dedicated sorting table with premarked bins.

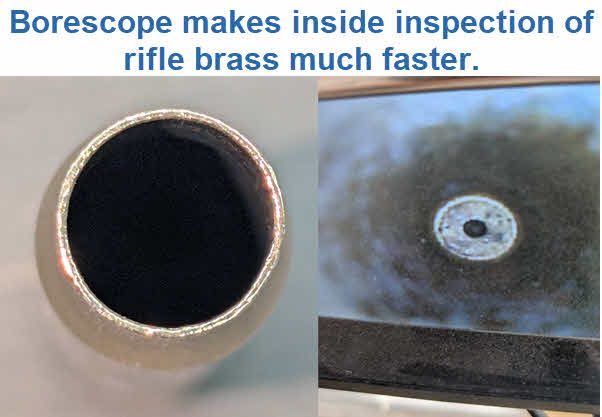

⚙️ Faster/Easier Tip:

A borescope makes the inspection of rifle brass much easier. Berdan is easy to spot and the device has a built in light.

🧠 Final Thoughts: Patience Pays Off

Sorting range brass takes time, but it’s worth it. A properly sorted batch means:

Consistent resizing and priming

Fewer damaged dies

Better accuracy and reliability

Follow the steps — remove trash, separate by diameter and height, and inspect carefully — and your reloading process will be faster, safer, and more rewarding.

Note: These are not hard rules, but rather general guidlines as some may want to decap or wash prior to different steps. However, when doing this, always be aware of the possibility of nested cases.